The official website of Kodera Electronics Co.,Ltd.

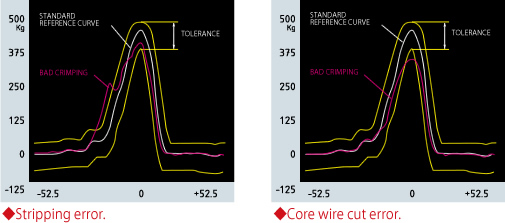

- Crimp Force Monitor.

- The load cell, which is installed in the ram of crimping unit, measures the precise crimping force for every terminal crimping. Since an encoder is used to control all the angles, measurement timing does not change regardless of voltage fluctuation.

- Crimp Force (Crimp Height) Automatic Setting.

- Crimp quality is controlled by the crimp height. Since crimp force is related to the crimp height, the C551SZe automatically adjusts the crimp force (crimp height), when the crimp force value is specified. Settings can be saved in memory function.

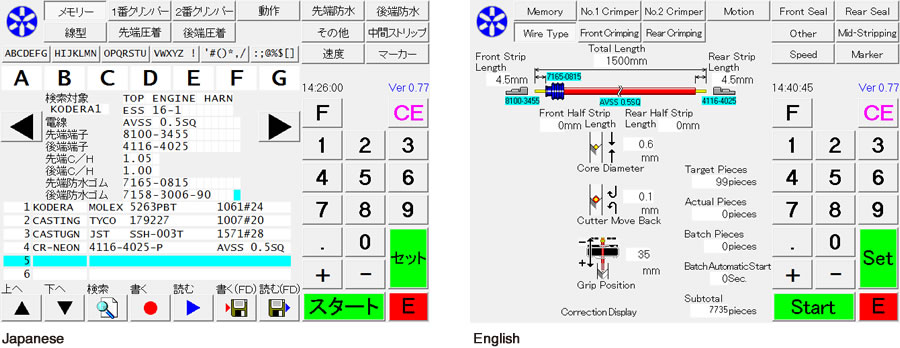

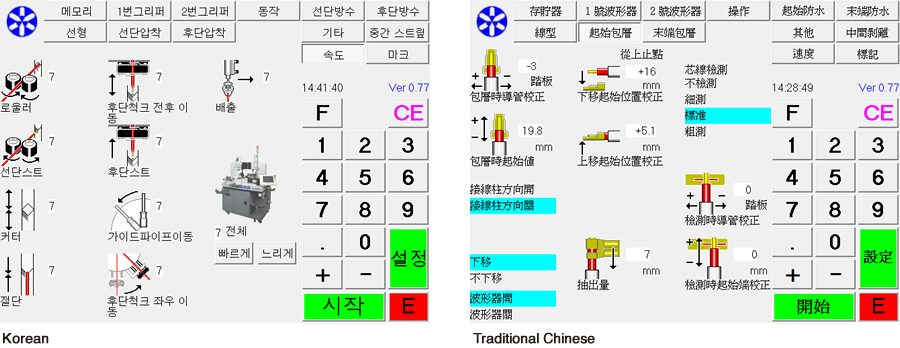

- Easy Operation with the Graphical Screen.

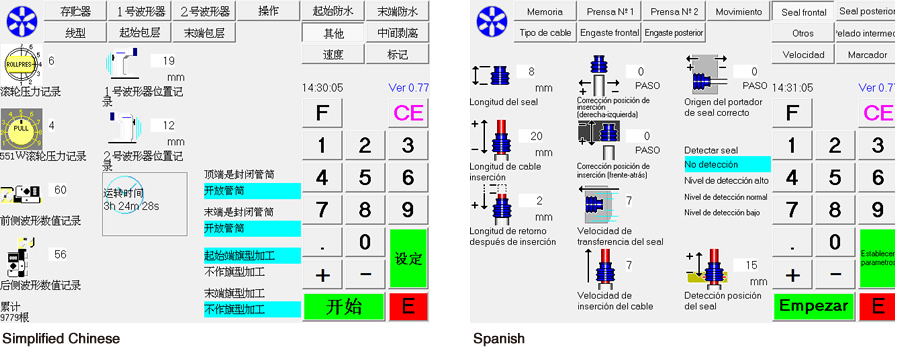

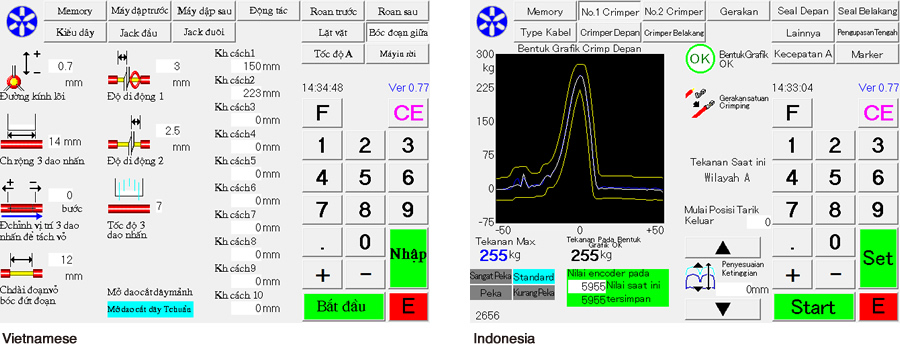

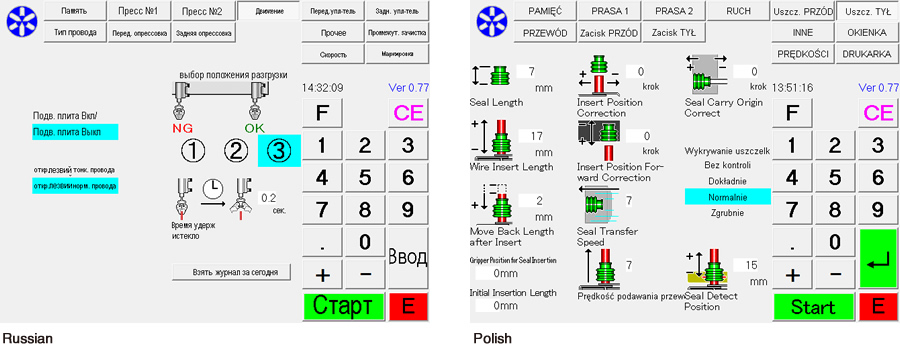

-

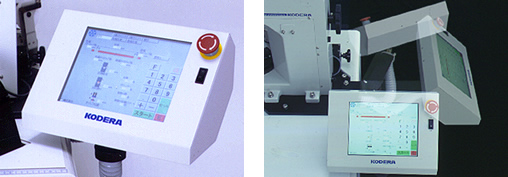

The large scale LCD touch panel provides graphic instructions for operation. The screen is designed for the operator's ease of use.

- Easy-to-operate operation panel.

-

The 180 degrees swivel arm of the control panel 180 degrees allows the operator to adjust the position of the screen in many ways. (C551Se,C555Se,C558Se)

Operation panel with back-light swivels 180 degree, so that the operator can check the operating condition from any position.(C550SZe series, ,C556SZe)

The seal again, the waste of the wire is reduced and continuous processing can be ensured. - Clear large size full-color LCD touch panel.

- 10.4 inch(211.2mm×158.4mm)size, 1677million full-color touch panel.

The interactive picture panel is available for 6 languages, Japanese, English, Korean, traditional Chinese, simplified Chinese, Indonesia, and Thailand.

SMART MECHANISM DRASTICALLY REDUCES PREPARATION TIME.

The same proven CASTING mechanism, where a single pair of verticle blades cuts and strips the wire, is used. Just enter the numeric parameters on the keypad.

Changing an applicator only requires one touch of a button. The large memory allows you to store information for up to 500※ different jobs and to recall this data at anytime for immediate production. All these features help shorten the preparation time when changing jobs.

※Unlimited memorization with using USB memory.

CONSTANT CRIMPING CONDITION.

By using guide pipe to shift down the wire, wire bending and crimping displacement can be prevented and a constant crimping condition can be ensured. Switching between post-feed and pre-feed is also possible by timer input.

REPOSITIONING CAN CAUSE THE POSSIBILITY OF CRIMPING.

Displacement. To prevent this, repositioning is eliminated and stable processing is realized by

[ STRIP → SENSOR CHCK → CRIMPING ] steps.

(C551Se/C511e・C555Se/C515e・C558Se/C518e)

Almost no idling is required.

Utilizing stepping motors in major drive mechanisms, the machine aliminates idlling almost completely.

Measurement Correction for Improved Accuracy.

Sometimes the processed length can be shorter than the displayed length, due to back tension and other factors. To correct these problems, this model includes a measurement correction feature to ensure accuracy.

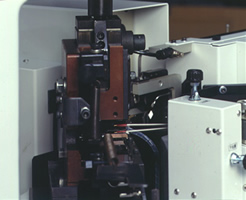

High-precision crimping press.

To provide an advance feature of crimp force monitor, it is critical to maintain the precision of crimping unit. This crimping unit is developed by KODERA and provides very precise crimping.

Crimping of Flag-shaped Terminals.

Allows switching from the standard terminal processing to the flag-shaped terminal processing with control panel.

Easy Operation with Memory Data Search.

Specify the job number in memory storage to recall the wire data.

Manual Crimping.

With control panel, you can perform the single press operation. In this manner, you can crimp the wire manually.

Adjustment of Front/Rear Cutter Settings.

You can set the front and rear blade differently. This is ideal when processing special type of wire, such as glass wire.

Shorter Training Period.

CASTUGNON has the same basic operation method and uses same word of KODERA's CASTING series. Therefore users who have experience with from CASTING series, can learn the basic operation quickly.

One Machine to Cover Thin and Thick Wire.

CASTUGNON covers a wide range of wire size: #32 - #12. You need only one machine to perform all different processing, which conventionally required three to four different machines. This provides great financial and business advantages.

Further Improved Processing Speed.

Utilizing the technology of the bestselling model C451A, provides higher processing speed and improved accuracies.

For Longer and Comfortable Operation.

The top plate is covered with a protective magnetic sheet to prevent damage from the maintenance and cleaning of applicator.

Applicator from Any Manufacturer Can be Used.

Using the attachment base of each manufacturer, you can attach and detach any type of applicator.

Minimum Loss with Step Feed.

Using memory function and step feed for fine settings,waste from test process is only a minimum. Faster and economical processing is ensured.

Roller In Accordance With Your Requirements.

Thick wire require a stronger grip while thin wires require a gentler one. Four types of rollers are available, from coarse knurled for strong grip, through fine knurled, sand-blasted to polyurethane for a weaker grip.

Choose a pair of proper rollers according to your needs.

The Latest KODERA Technology Is Found Here.

Thick wire require a stronger grip while thin wires require a gentler one. Four types of rollers are available, from coarse knurled for strong grip, through fine knurled, sand-blasted to polyurethane for a weaker grip.

Choose a pair of proper rollers according to your needs.

Guide Pipes For Accurate Crimping.

Using the correct guide pipe means you can get the tip of the wire very close to the crimping terminal resulting in much more precise crimping. You can choose from 12 different sizes of guide pipes to match the thickness of your wire.

(φ1/φ1.25/φ1.5/φ1.75/φ2/φ2.25/φ2.5/φ3/φ3.5/φ4/φ5/φ6)

Processing date record of every lead. [C55Xe series]

The processing date and log can put into USB memory.

The date can keep as product record and useful for quality control.

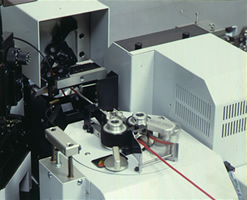

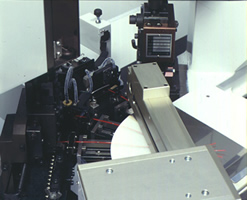

Mechanical Design Assures Stable Performance.

A swivel turntable, with little inertia, transports the wires from the cutting and stripping position to the crimping position. The newly developed 45Aaswivel drum is very logical, efficient and fast in transporting wires, thus ensuring maximum stability in the quality of processed wires.

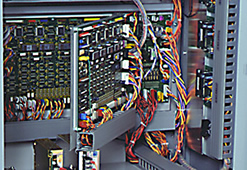

Defect Free.

The main theme of KODERA, "Zero Defects", is aimed towards customer satisfaction. In order to attain this goal, efforts have never been spared. Use of a cooling fan specific for the motor control circuit is one example of our cumulative efforts.

Newly Employ Gripper For Rear End Stripping.

In order to further improve the rear end finish of short wires, the gripper mechanism has been recently employed. A quick response stepping motor can be easily adjusted to gently but firmly grasp the wire.

For Easy Disposal Of Stripped Slugs.

Stripped insulation slugs and terminal carrier waste are automatically separated and dropped into separate disposal containers. This eliminates the trouble of separating and disposing of the slugs later.